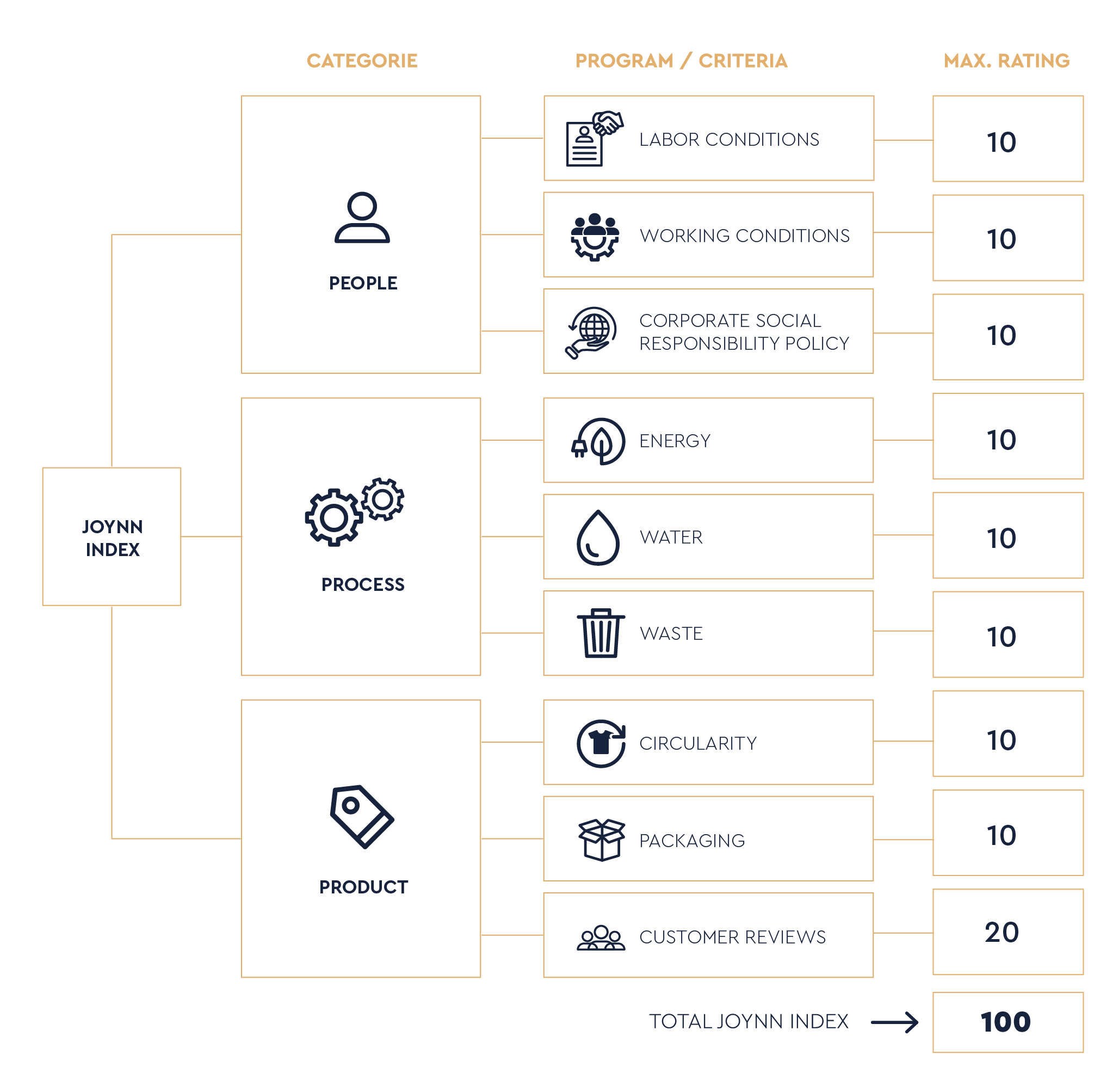

THE JOYNN INDEX

The Joynn Index is a company profile and a report about the ratings.

When a customer is matched with a manufacturer they will receive the company profile and the Index report. This report will be also additionally advised and checked on by a independent organization

The goal of the report is to improve their business towards a circular economy.

The Index has three categories:

- People

- Process

- Product

A manufacturer has to work with on all categories to become a sustainable manufacturer.

For a manufacturer the biggest asset are the people working for the company. To achieve the best policy for the people we have three criteria where we work on together with the manufacturer.

Labor conditions

We carefully check to ensure that all products are made in compliance with the legal minimum wage standards, alongside proper employment contracts and workers’ rights. This includes an emphasis on health and safety regulations, as well as other essential labor conditions, to guarantee a safe and just working environment for all individuals involved in the production process.

Working conditions

The workplace must be provided with good hygiene practices to ensure a healthy environment for all employees. This includes maintaining clean sanitary facilities, having well-structured emergency plans, ensuring proper evacuation procedures, implementing stringent machine safety protocols, and guaranteeing sufficient ventilation to promote air quality and comfort. All these factors are essential for creating a safe and productive work environment.

CSR Policy

The manufacturer can make a significant difference with a well-defined Corporate Social Responsibility (CSR) policy, especially if they actively invest in local communities. This investment can take many forms, such as supporting educational initiatives, providing job training programs, and contributing to local infrastructure development.

Additionally, by sourcing suppliers who adhere to ethical standards and align with the company’s core values, they can promote sustainable practices and ensure fair treatment of workers throughout the supply chain.

To make a product, you need a comprehensive process to efficiently produce it. This process encompasses various factors, including energy consumption, water usage, and waste management. Each of these elements plays a crucial role in shaping the overall sustainability of the production process. The ultimate goal of establishing these criteria is to create a more sustainable and environmentally friendly process that minimizes negative impacts on our planet while maximizing resource efficiency.

Energy

In the textile factory, a considerable amount of energy is consumed daily to support various processes and operations. Our primary goal is to significantly reduce energy usage and to transition towards utilizing more sustainable and green energy sources that are friendly to the environment.

Water

The water usage in a manufacturing facility is primarily focused on strategies and practices aimed at saving and recycling water effectively. This involves not only the careful monitoring of water consumption but also the implementation of innovative technologies and processes designed to minimize waste while ensuring that the necessary water quality standards are maintained.

Waste

In every production process of textiles, there is an inevitable generation of waste, and the question of what to do with this waste or how to effectively reduce it will be the very first step that must be addressed.

A comprehensive approach to managing textile waste not only contributes to environmental sustainability but also enhances the overall efficiency of production processes.

The responsibility of a product will need to change significantly, because that change will initiate the comprehensive process of how to effectively develop a product and how it can be re-used or recycled efficiently at the end of its life cycle, thereby promoting sustainability and reducing environmental impact.

Circularity

The current economy model is fundamentally based on a linear approach, which not only generates a significant amount of waste, but also leads to a considerable loss of valuable resources.

When we talk about transitioning towards a circular economy, we are essentially discussing a transformative process that focuses on creating products designed from the outset to be repurposed, reused, or recycled.

Packaging

Reducing the waste generated from the packaging of textile products is one of the main topics of discussion in today’s sustainability efforts. Transitioning to packaging that is not only more eco-friendly but also biodegradable is a crucial first step towards minimizing our environmental impact.

Customers

The customers are playing a crucial and transformative role in changing the economy model into a circular one, because they create the demand for sustainable practices and environmentally friendly products.

The more people consciously choose to buy products in a responsible and sustainable manner, the quicker the textile industry will adapt and change its practices towards more eco-friendly alternatives.